In our ever-evolving world, technological advancements continue to change industries, sparking enhanced efficiency and productivity. Among these groundbreaking innovations, UV curing stands out as a fascinating process with diverse applications, ranging from manufacturing and printing to dentistry and electronics. This blog aims to explore the concept of UV curing, its underlying principles, and its far-reaching benefits. Furthermore, we will delve into the vital role played by Intellego and how our dosimeters offer companies an effective and accurate validation tool to ensure precise radiation exposure in UV curing processes.

Understanding UV Curing:

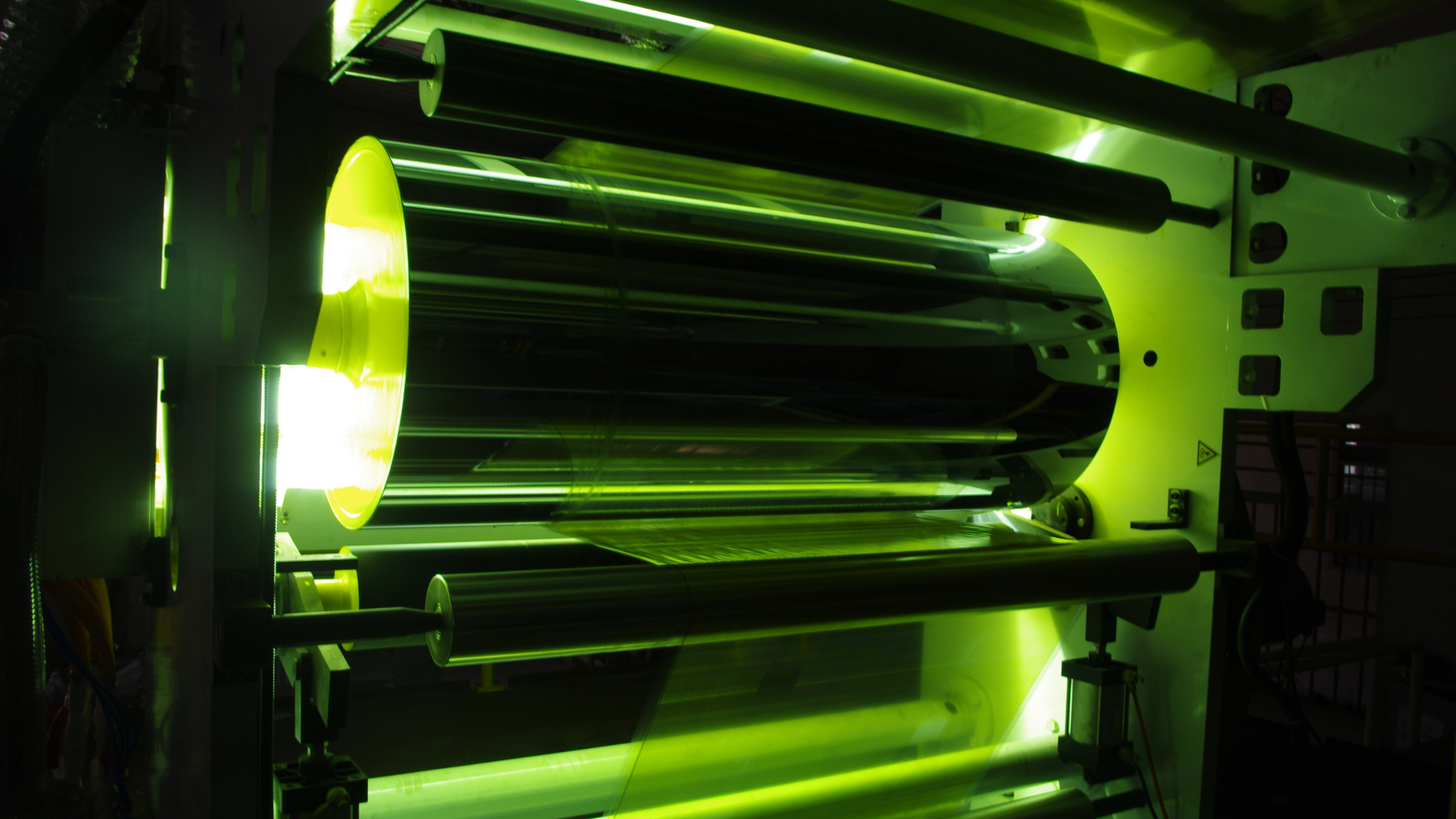

UV curing, or ultraviolet curing, is a photochemical process that employs ultraviolet light to initiate a chemical reaction, transforming liquid or resinous materials into solid, durable products. This technique is particularly effective for materials that are sensitive to heat or that require rapid curing. UV lights activate specific substances in the liquid, creating a solid polymer network through a reaction. This UV technology and process are implemented daily in many production lines across the world.

Applications of UV Curing

The versatility of UV curing has led to its adoption in various industries, delivering numerous advantages over traditional curing methods. Some prominent applications include:

- Printing and Packaging: UV curing enables high-speed production, instant drying, and vibrant, durable prints. It ensures sharper images and reduced ink smudging, benefiting the printing industry.

- Coatings and Finishes: UV-curable coatings offer exceptional chemical and scratch resistance, making them ideal for automotive, electronics, and furniture manufacturing, as well as wood finishes.

- Adhesives and Bonding: Rapid-curing UV adhesives facilitate strong bonding of diverse materials like glass, plastics, and metals, benefiting electronics assembly and medical device manufacturing.

- Dental and Medical Fields: UV curing transforms dentistry with fast-curing dental composites and adhesives. In the medical sector, UV-curable materials are used for device assembly, wound care, and implant coatings.

Benefits of UV Curing:

UV curing’s popularity is due to its many benefits:

- Increased Productivity: Rapid curing times enable high-speed production, reducing processing cycles and increasing overall efficiency for manufacturers.

- Enhanced Product Quality: UV-cured products exhibit superior properties such as excellent adhesion, chemical resistance, hardness, and scratch resistance, ensuring consistent quality.

- Cost-effectiveness: Although the initial investment in UV curing equipment might be higher, the long-term cost savings due to reduced energy consumption and increased production speed can make UV curing a cost-effective solution.

- Improved quality: UV-cured materials often exhibit superior properties, such as enhanced scratch resistance, chemical resistance, and overall durability. Fast curing reduces the risk of dust or contaminants settling on the surface, resulting in a more consistent and high-quality finish.

Intellego’s Role in UV Curing Dosimetry

Intellego plays a crucial role in UV curing dosimetry, providing cutting-edge solutions for manufacturers worldwide. Our dosimeters are science-backed tools that measure and record the UV dose received during curing. This enables users to verify the correct amount of radiation exposure, ensuring consistent curing results, preventing under-curing or over-curing, and maintaining the highest product quality standards.

With Intellego’s dosimeters, industries can optimise UV curing processes, increase efficiency, accurately measure the dose, and reduce material waste. Our commitment to innovation, reliability, and customer satisfaction continues to drive advancements in dosimetry and fortify the success of UV curing applications across various sectors.

UV curing’s ability to efficiently cure liquid materials has propelled its adoption in numerous industries, revolutionising manufacturing processes and enhancing product quality. With Intellego’s accurate dosimeters, manufacturers can now ensure precise radiation exposure during UV curing, yielding consistent and superior results. UV curing, combined with precise dosimetry, will undoubtedly fuel innovation and lead to a brighter, more sustainable future as we explore new possibilities.

To find out more about Intellego’s UV Assure dosimeters, click here.

About Intellego Technologies AB

Intellego Technologies is a research and development company, headquartered in Solna, Sweden. Founded in 2011, Intellego has grown to become the global leader in colorimetric indicators that are utilized worldwide to visually validate the dose of ultraviolet irradiation delivered to surfaces. Through its patented photochromic technology, Intellego manufactures standard and customized indicators that make the benefits of ultraviolet light visible and promotes the safe, effective and efficient use of UV applications. Intellego’s products support better outcomes with ultraviolet devices in healthcare, food and beverage manufacturing, environmental services, and more. For more information about Intellego, visit Intellego-Technologies.com. For more information on Intellego’s line of colorimetric indicators, visit UVCdosimeters.com.