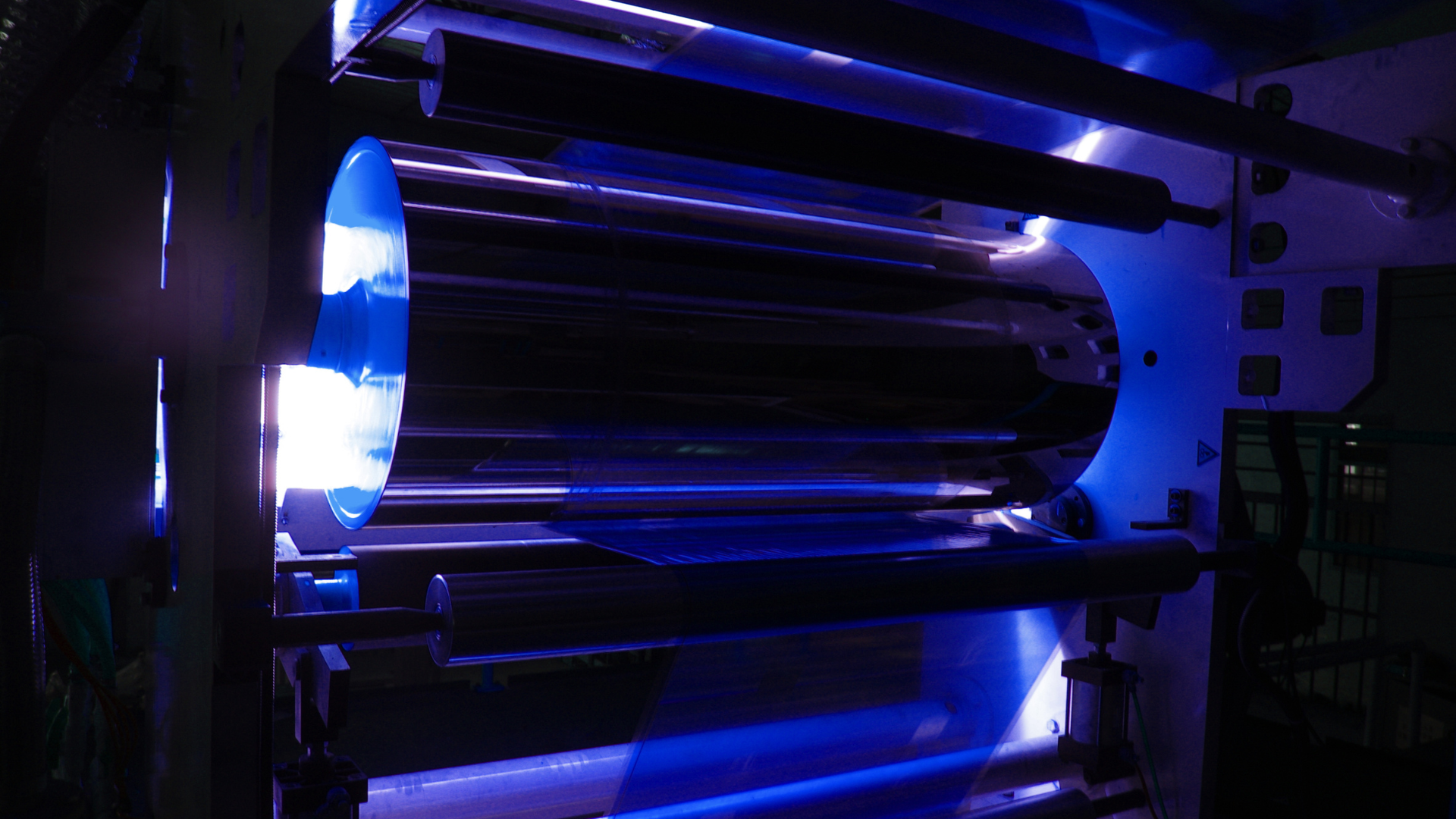

Precision, efficiency, and reliability are crucial for success in the modern manufacturing industry. The emergence of new UV technologies has transformed the way we handle UV curing. In this article, we explore the benefits of modern UV curing dosimeters.

Dosimeters for Modern UV Curing

Advancement in UV technology ushered in the age of UV dosimeters, with UV Assure Dosimeters establishing a new standard for UV curing quality. These modern UV irradiation dosimeters are changing the way we monitor UV irradiation during the curing process, providing a plethora of benefits.

Real-Time Monitoring:

When compared to earlier forms of UV irradiation, adding real-time monitoring is a major improvement. To guarantee the best curing results, modern UV card dosimeters provide instantaneous feedback when a predetermined dose or energy level is reached. Manufacturers can now confidently guarantee consistent and predictable outcomes from the curing process. As a result of mitigating under-dosing, product quality is enhanced, waste is decreased, customer complaints are reduced, and margins and profits are increased.

Accurate and Extensive Data:

UV Assure dosimeters can be used to track UV dose data throughout the entire curing process. This extensive data, which can be logged in real time using the UV Assure app, gives manufacturers a better understanding of UV exposure patterns, allowing them to optimize the curing process and ensure quality standards are met.

Efficient and Cost-Effective:

UV technology is becoming increasingly efficient and cost-effective, allowing for the optimization of the production process and, in turn, a bigger return on investment for users. The use of UV Assure Dosimeters improves operational efficiency by eliminating the need for frequent calibration and manual analysis, cutting down on periods of machine downtime, and increasing overall productivity. These dosimeters optimize the validation and efficiency of UV curing equipment, resulting in cost and time savings.

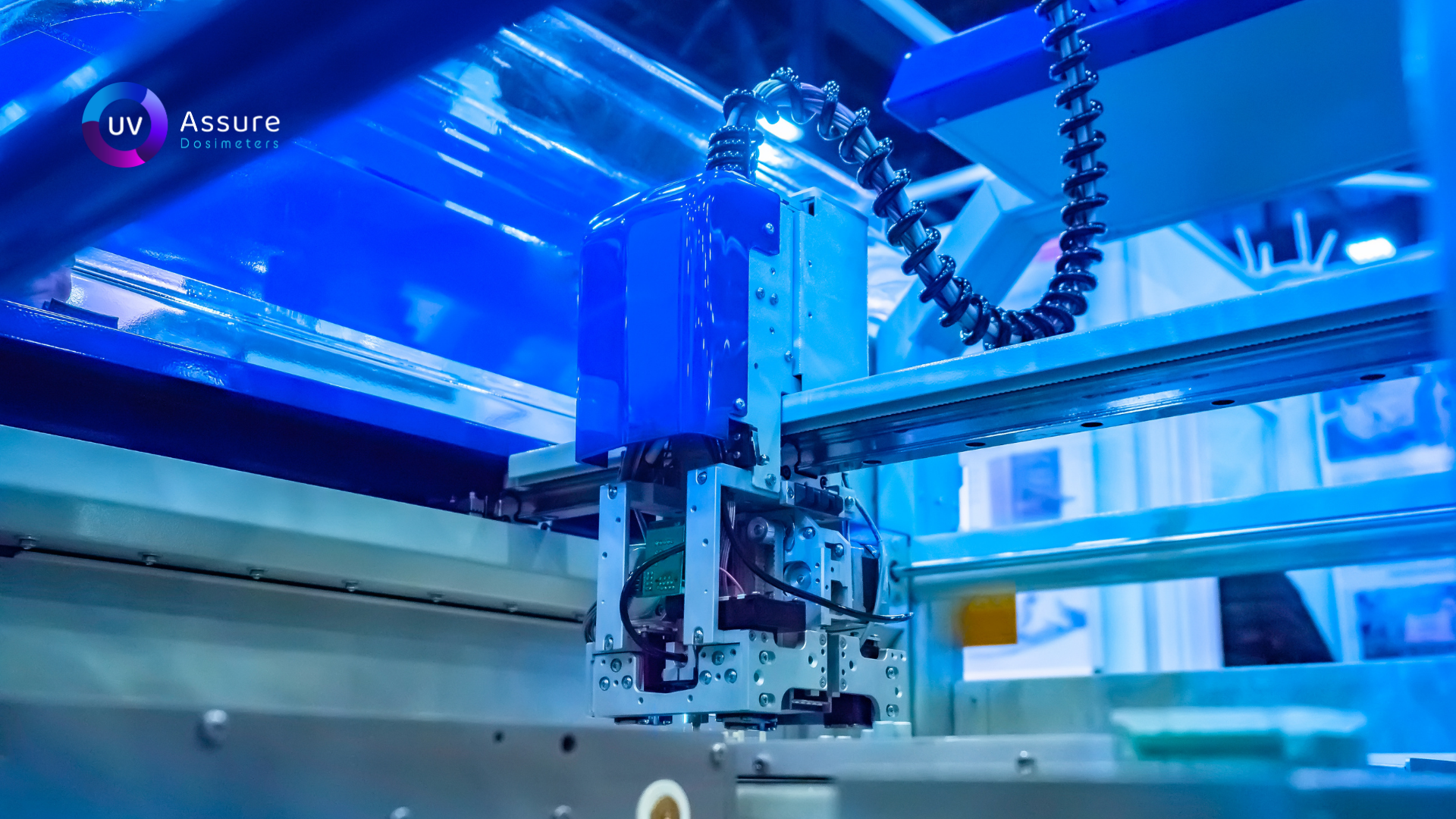

Adaptable and Remote Monitoring:

Due to their material, slimness, and flexibility, dosimeter cards can be used in narrow spaces and withstanding heat and humidity, making them ideal for use in a wide variety of curing environments. UV Assure dosimeters enable remote placement, ensuring the safety and convenience of workers at all times.

Data-Driven Decision Making:

UV-curing dosimeters are extremely useful instruments that support data-driven decision-making. By detecting trends and variations within the curing process, manufacturers can quickly identify potential issues and take appropriate action to maintain a consistent level of product quality. This helps to mitigate challenges and reduce errors throughout the production process. Data that is stored in the UV Assure App, can be transferred easily, for example, to a cloud solution for long-term storage and quality insurance or for statistical purposes.

Improving Industry Standards:

As the manufacturing sector develops, greater emphasis is placed on maintaining higher quality standards. By using advanced UV technology and reliable UV dosimeters, industries can not only meet but surpass established standards, giving them a competitive edge in the global market.

What Does it All Mean?

In conclusion, UV technology is evolving. By embracing the future of UV curing, you open doors for accuracy, efficiency, and dependability and unlock a new era of quality manufacturing that stands out.

About Intellego Technologies AB

Intellego Technologies is a research and development company, headquartered in Solna, Sweden. Founded in 2011, Intellego has grown to become the global leader in colorimetric indicators that are utilized worldwide to visually validate the dose of ultraviolet irradiation delivered to surfaces. Through its patented photochromic technology, Intellego manufactures standard and customized indicators that make the benefits of ultraviolet light visible and promotes the safe, effective and efficient use of UV applications. Intellego’s products support better outcomes with ultraviolet devices in healthcare, food and beverage manufacturing, environmental services, and more. For more information about Intellego, visit Intellego-Technologies.com. For more information on Intellego’s line of colorimetric indicators, visit UVCdosimeters.com.