The manufacturing sector has seen remarkable advancements throughout its history, which have resulted in the transformation of production procedures and an improvement in product quality. The use of ultraviolet light to cure substances and surfaces stands out among these significant advancements as an innovative technology that has significantly influenced the manufacturing sector. This article delves into the background of ultraviolet (UV) curing, its importance across multiple sectors, and the role UV dosimeters play in maximizing output.

The First Glimpse of UV Curing:

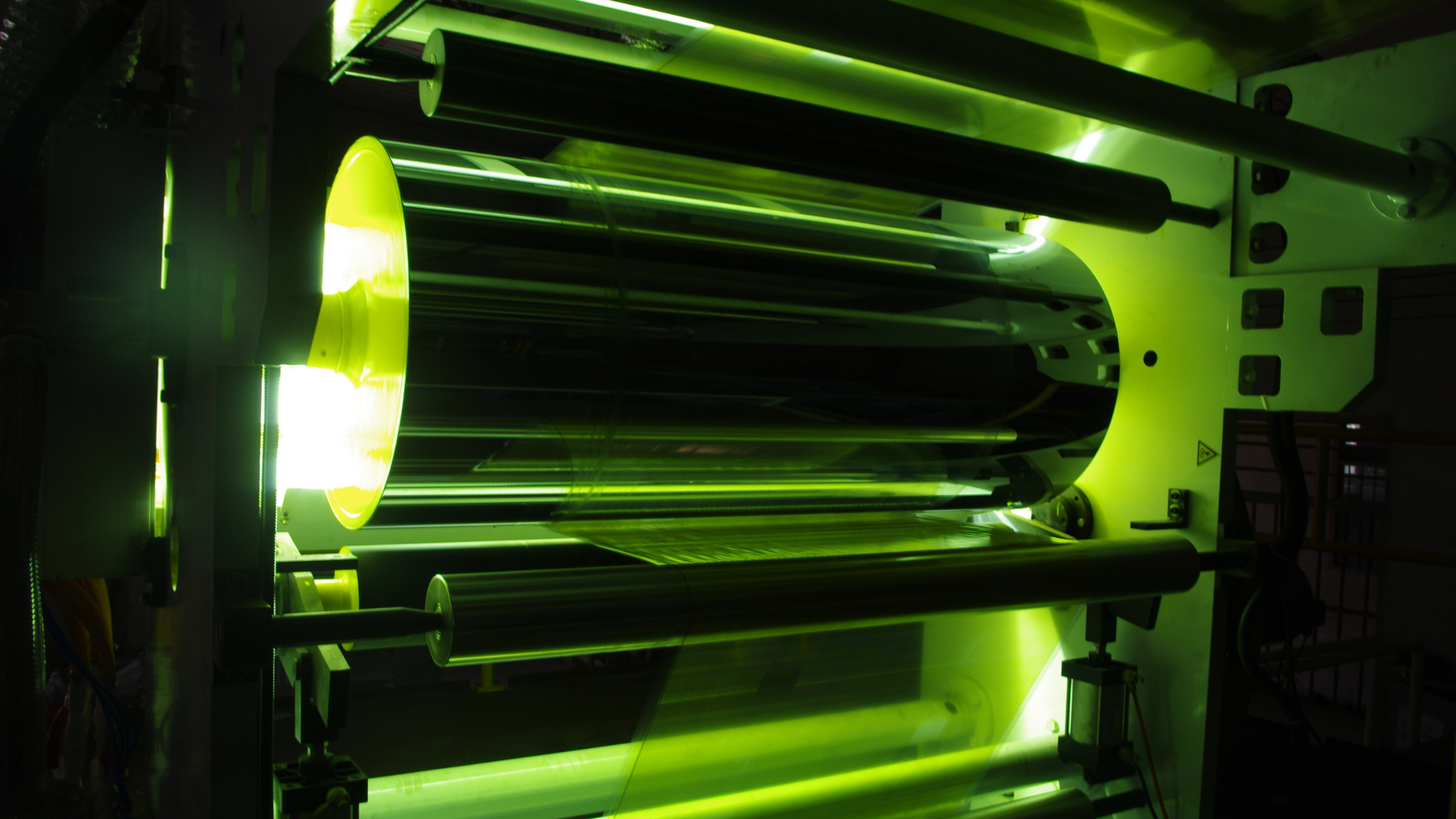

UV light for curing was first discovered in the early 1960s, but it wasn’t until the 1980s that it gained commercial prominence through rapid advances in chemicals and equipment technology. The true capabilities of UV curing became increasingly apparent. Researchers found that certain chemical formulations could undergo rapid polymerization when exposed to ultraviolet radiation. This innovation paved the way for UV curing to be adopted across a vast range of industries, including automotive, electronics, printing, flooring, dentistry, and aerospace manufacturing – just to mention a few.

The Development of UV Curing:

UV curing has often caused a fundamental change in production practices. Traditional curing processes required more time and generated more heat, both of which had the potential to damage sensitive substrates and reduce the efficiency of production. Technological advancements have allowed manufacturers to cure without overheating. Coatings and adhesives that were cured with ultraviolet light hardened in seconds, thereby enhancing the production process.

Uses of UV Curing in Manufacturing:

UV Curing has established itself as a highly adaptable and significant production method, making it ideal for a variety of manufacturing industries, such as:

- Electronics and Semiconductors

- Medical Devices

- Graphics and Printing

- Aerospace and Automotive

- Wood Coatings

The Vital Function of UV Dosimeters

As UV curing becomes more widespread, the demand for accuracy, validation, and quality control has increased substantially, making the implementation of UV dosimeters even more crucial for the manufacturing process. UV Assure Dosimeters provide the invaluable capability of real-time monitoring and precise measurement of UV energy levels, assuring adequate UV exposure and avoiding the risk of under-dosing.

Conclusion

UV curing has become a significant production process component, changing how we manufacture across industries. This process has risen to the forefront of cutting-edge production methods due to its rapid drying times, low heat output, and eco-friendliness. Innovations, such as LED lamps, will further increase eco-friendliness by lowering energy consumption and moving away from mercury.

With their real-time monitoring and accurate readings, UV dosimeters have taken the effectiveness and dependability of UV curing to new heights. And when combined with the UVAssure App, you have an even more efficient and reliable quality control system.

With its substantial developments and positive effects on diverse industries, UV curing technology will continue to be at the forefront of production, guaranteeing quality, efficiency, and accuracy.

About Intellego Technologies AB

Intellego Technologies is a research and development company, headquartered in Solna, Sweden. Founded in 2011, Intellego has grown to become the global leader in colorimetric indicators that are utilized worldwide to visually validate the dose of ultraviolet irradiation delivered to surfaces. Through its patented photochromic technology, Intellego manufactures standard and customized indicators that make the benefits of ultraviolet light visible and promotes the safe, effective and efficient use of UV applications. Intellego’s products support better outcomes with ultraviolet devices in healthcare, food and beverage manufacturing, environmental services, and more. For more information about Intellego, visit Intellego-Technologies.com. For more information on Intellego’s line of colorimetric indicators, visit UVCdosimeters.com.