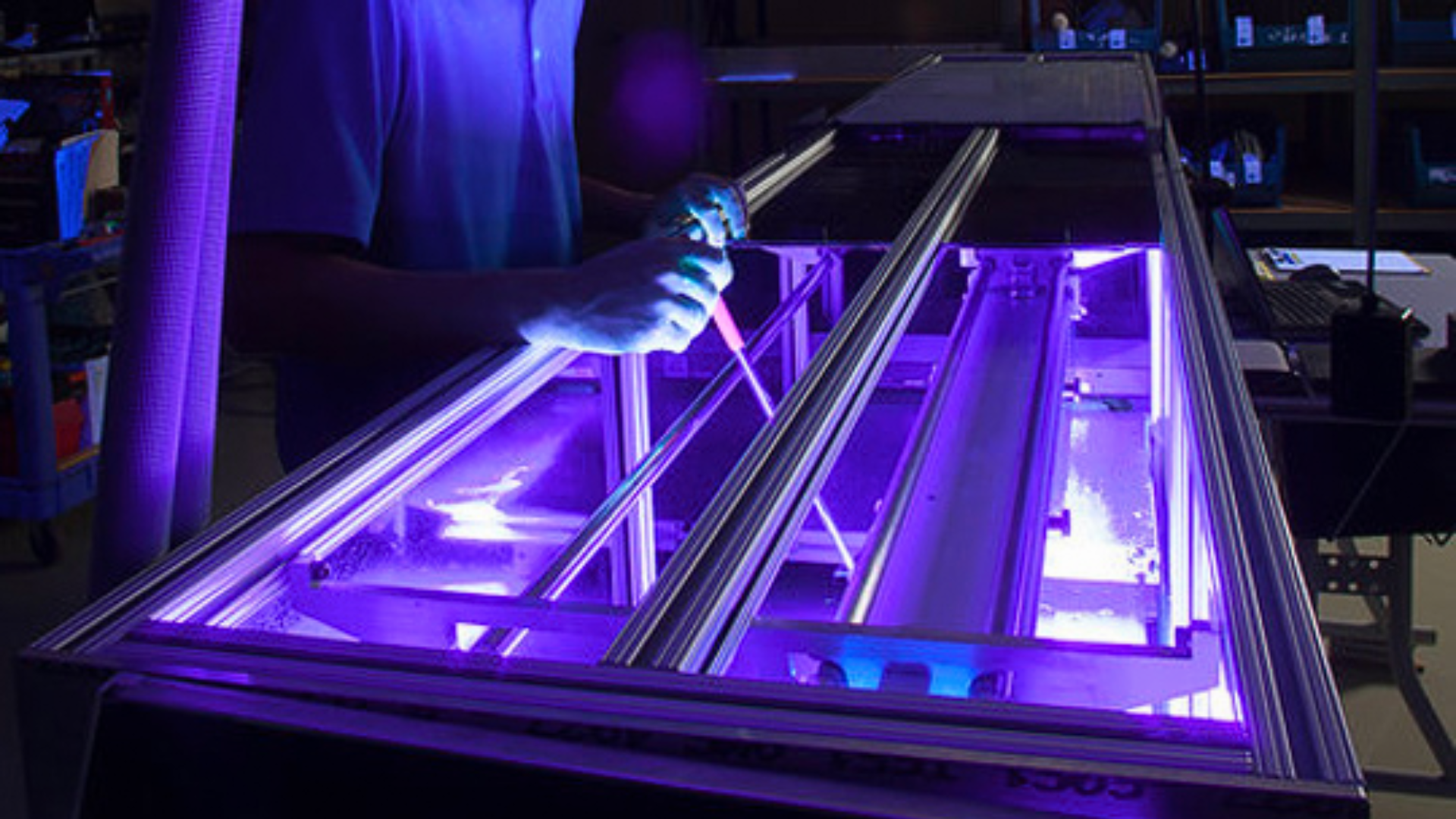

Like most manufacturing processes, using UV as a curing method also has its own distinct array of challenges. By understanding these challenges and implementing effective strategies, manufacturers can optimize their UV curing processes and ensure consistent, high-quality results. In this blog, we aim to provide practical solutions and insights to help manufacturers overcome these challenges and optimize their UV curing processes.

Benefits of UV Curing

UV Curing offers a variety of benefits over traditional curing methods. Firstly, UV curing is a fast process that significantly reduces production time. Unlike thermal curing, which requires hours or even days to complete, UV curing achieves a full cure in seconds or minutes. This speed allows manufacturers to increase their production output and meet demanding deadlines.

UV curing is a cost-effective solution. With traditional curing methods, manufacturers often face high energy costs due to extended curing times. UV curing, on the other hand, utilizes UV lamps that consume less energy and generate less heat. This reduces not only energy costs but also the risk of thermal damage to sensitive materials.

UV curing also offers excellent adhesion properties, resulting in coatings that are highly durable, resistant to chemicals, and have superior adhesion, ensuring high-quality finished products.

UV Curing Challenges and Solutions

Uneven Curing

Achieving uniform curing across different materials and surfaces can be a complex task, leading to quality issues and production delays. Inconsistent curing can result from factors such as variations in product thickness, surface properties, improper lamp intensity, incorrect exposure times, and lamp-to-substrate distance.

To overcome this challenge, manufacturers should conduct thorough testing and validation to determine the optimal curing parameters for each material and surface. Additionally, implementing quality control measures such as real-time monitoring and feedback tools can help identify and fix curing errors promptly.

Equipment maintenance and downtime:

Another hurdle to UV curing is selecting the right equipment. Without the proper equipment, manufacturers may encounter limitations in their curing process, which can have a negative effect on productivity. In addition, UV lamps require routine maintenance and replacement to function properly. Equipment maintenance and downtime can disrupt production schedules.

To address this challenge, manufacturers should invest in UV curing equipment from reputable suppliers with a track record of reliability and durability. UV Dosimeters can be utilized to ensure the functionality of the equipment being purchased. To minimize unexpected downtime, regular maintenance and calibration of UV lamps, as well as the use of UV dosimeters to ensure the lamps are irradiating correctly, should be implemented.

Controlling UV radiation exposure:

During the curing process, UV curing generates heat, which can cause thermal damage to sensitive materials. In order to avoid damage, manufacturers must carefully monitor and optimize curing parameters. Overexposure to UV radiation can lead to the discoloration, yellowing, or degradation of certain materials.

Manufacturers should carry out extensive testing to determine the best UV lamp intensity and exposure time for each material. This can be accomplished by monitoring exposure data with a dosimeter and logging it to fine-tune irradiation time.

Cost Considerations and ROI:

We are not going to lie; implementing UV curing technology can incur significant up-front expenses, such as the purchase of UV curing equipment, installation, and training. However, although UV curing may seem expensive at first, the long-term economic advantages make it a viable option for the current manufacturing industry. In addition, the ongoing costs that must be accounted for, such as the consumption of energy, maintenance, and the replacement of UV lamps, should be considered.

In order for manufacturers to effectively address this challenge, they need to conduct an in-depth cost analysis to determine the possible cost savings and benefits of incorporating UV curing technology into their processes. This includes considering aspects such as greater manufacturing output, reduced energy usage, enhanced product quality, and lower scrap or rework rates. Collaborating with UV curing equipment suppliers to develop customized financing options or leasing agreements can also help manage upfront costs.

The future of UV curing in manufacturing

Despite the challenges UV curing presents to manufacturers, the benefits and potential of this technology make it a valuable asset in the manufacturing industry. As manufacturers persist in their search for innovation and problem-solving, the pivotal role of UV curing in strengthening productivity, efficiency, and product quality will undoubtedly rise.

To conclude, UV curing technology has the potential to enhance manufacturing processes. Manufacturers can overcome the challenges discussed and unlock the full potential of UV technology by putting the right strategies in place.

Contact our sales team today and find out how we can help you streamline your production processes.

About Intellego Technologies AB

Intellego Technologies is a research and development company, headquartered in Solna, Sweden. Founded in 2011, Intellego has grown to become the global leader in colorimetric indicators that are utilized worldwide to visually validate the dose of ultraviolet irradiation delivered to surfaces. Through its patented photochromic technology, Intellego manufactures standard and customized indicators that make the benefits of ultraviolet light visible and promotes the safe, effective and efficient use of UV applications. Intellego’s products support better outcomes with ultraviolet devices in healthcare, food and beverage manufacturing, environmental services, and more. For more information about Intellego, visit Intellego-Technologies.com. For more information on Intellego’s line of colorimetric indicators, visit UVCdosimeters.com.