Why Is Validation In The UV Industry So Important?

In a world where safety and well-being are top priorities, Ultraviolet (UV) technology has emerged as a true game-changer in ensuring cleanliness and disinfection. From hospitals and hotels to food processing plants, UV technology is becoming the go-to solution for eliminating harmful microorganisms effectively. Yet, the key to its success lies in something very human: data-driven UV validation. And in this crucial aspect of UV technology compliance, Intellego is undoubtedly a pioneer.

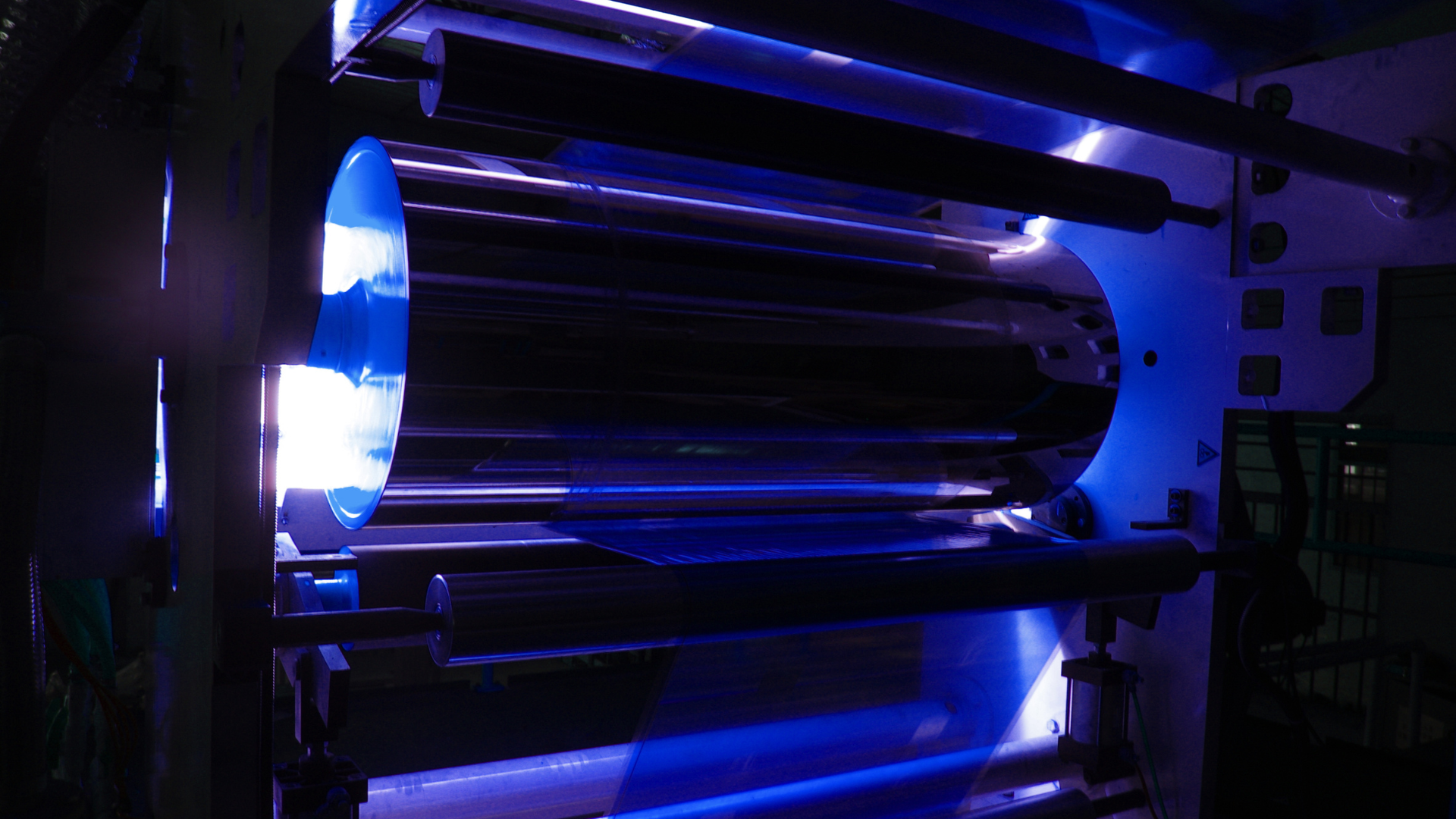

UV Technology: A Beacon of Hope

Ultraviolet technology, especially the UV-C variety, harnesses the power of ultraviolet light to neutralize a broad spectrum of pathogens. We’re talking about everything from bacteria and viruses to mould and fungi. This germ-killing ability makes UV technology incredibly attractive to industries where maintaining strict hygiene standards is a must.

The Growing Popularity of UV Technology and the Significance of Data-Driven Validation

The use of UV technology has skyrocketed recently. It’s no surprise, considering its effectiveness in disinfection. No matter if you’re in the healthcare field, hospitality, or manufacturing, UV technology provides an eco-friendly and chemical-free way to ensure surfaces and air are free from harmful microorganisms.

But as the use of UV technology grows, so does the need for stringent validation. This validation ensures that UV technology adheres to the standards and regulations specific to each industry.

Data-driven validation is essentially the process of using real-world data and scientific evidence to prove that a UV system does what it claims to do—effectively neutralizing microorganisms. It’s a crucial step in making sure UV technology complies with industry-specific rules.

At its core, data-driven validation involves delving deep into the science behind UV-C technology. UV-C rays, which are shorter than UVA and UVB rays, are very effective. When microorganisms are exposed to UV-C light, their genetic material breaks down. It’s like dismantling the tiny building blocks of life, rendering them incapable of causing infections or reproducing.

To validate a UV system, you collect data on various factors, like how much UV-C light is used, the wavelength, and how long the exposure lasts. This critical data ensures that the UV system gets rid of harmful microorganisms without harming humans or the environment.

Navigating UV Technology Regulations: How Does Intellego Fit This Mold?

The regulations for UV technology are complex and can vary from industry to industry. For instance, UV devices used in healthcare might fall under medical device regulations, while those used in water treatment must adhere to specific standards. Intellego knows the ins and outs of these regulations and works diligently to ensure that UV technology stays within compliance.

Industry associations and regulatory bodies are a significant part of the UV technology world. They develop and enforce standards to ensure UV systems meet safety and performance criteria. Data-driven validation plays a crucial role here because it relies on real-world evidence to show compliance. This process helps manufacturers, healthcare providers, and other stakeholders confidently use UV technology, knowing it meets the requirements for safe and effective operation.

Where Does Intellego Fit Into The UV Validation Space?

Intellego isn’t just following the pack; it’s leading the way when it comes to UV technology compliance. Our company understands that the success of UV technology relies on more than just theoretical claims—it requires solid scientific evidence. Intellego’s UV dosimeters, like the 254UVC Tri Card and the 254UVC Quick Check, undergo thorough testing and evaluation. These dosimeters are essential tools for validating UV-C disinfection systems, making sure they deliver the promised level of germicidal effectiveness.

Intellego is continuously innovating its dosimeters to keep up with the ever-evolving UV technology landscape. These dosimeters provide real-time, measurable data, allowing users to accurately verify the effectiveness of UV systems. This commitment to innovation aligns perfectly with the dynamic nature of UV technology. Intellego doesn’t stop at dosimeters. The company offers a holistic approach to UV technology compliance, including consultation and training, to help organizations implement UV technology effectively. This ensures that clients have not only the right tools but also the knowledge to use them optimally.

As UV technology continues to advance, its role in ensuring health and safety across industries becomes even more significant. Intellego’s dedication to data-driven validation guarantees that UV systems can be trusted to deliver high-level disinfection without compromise.

By providing the necessary tools and knowledge for compliance, Intellego empowers organizations to make the most of UV technology. Together, we’re building a future where cleanliness and disinfection aren’t just ideals but real-life, achievable goals that protect public health and well-being.

Data-driven validation is at the heart of UV technology compliance. Intellego’s unwavering commitment to this essential aspect ensures that UV systems are a trusted solution for disinfection in various industries. As UV technology continues to make our world cleaner and safer, Intellego stands proudly as a trusted partner in achieving these vital goals.

About Intellego Technologies AB

Intellego Technologies is a research and development company, headquartered in Solna, Sweden. Founded in 2011, Intellego has grown to become the global leader in colorimetric indicators that are utilized worldwide to visually validate the dose of ultraviolet irradiation delivered to surfaces. Through its patented photochromic technology, Intellego manufactures standard and customized indicators that make the benefits of ultraviolet light visible and promotes the safe, effective and efficient use of UV applications. Intellego’s products support better outcomes with ultraviolet devices in healthcare, food and beverage manufacturing, environmental services, and more. For more information about Intellego, visit Intellego-Technologies.com. For more information on Intellego’s line of colorimetric indicators, visit UVCdosimeters.com.