UV dosimeters play a crucial role in UV disinfection and curing processes, ensuring accurate measurement of UV exposure. They enhance safety in healthcare settings, quality in manufacturing, and the overall effectiveness of ultraviolet light applications. Let’s explore the proper use of Intellego’s UV dosimeters, aligning our information with the latest industry insights.

Understanding UV Dosimeters

UV dosimeters are designed to measure UV exposure. They serve as critical tools in industries using UV technology for disinfection and curing. They ensure that UV light is applied at the correct intensity and duration for optimal results.

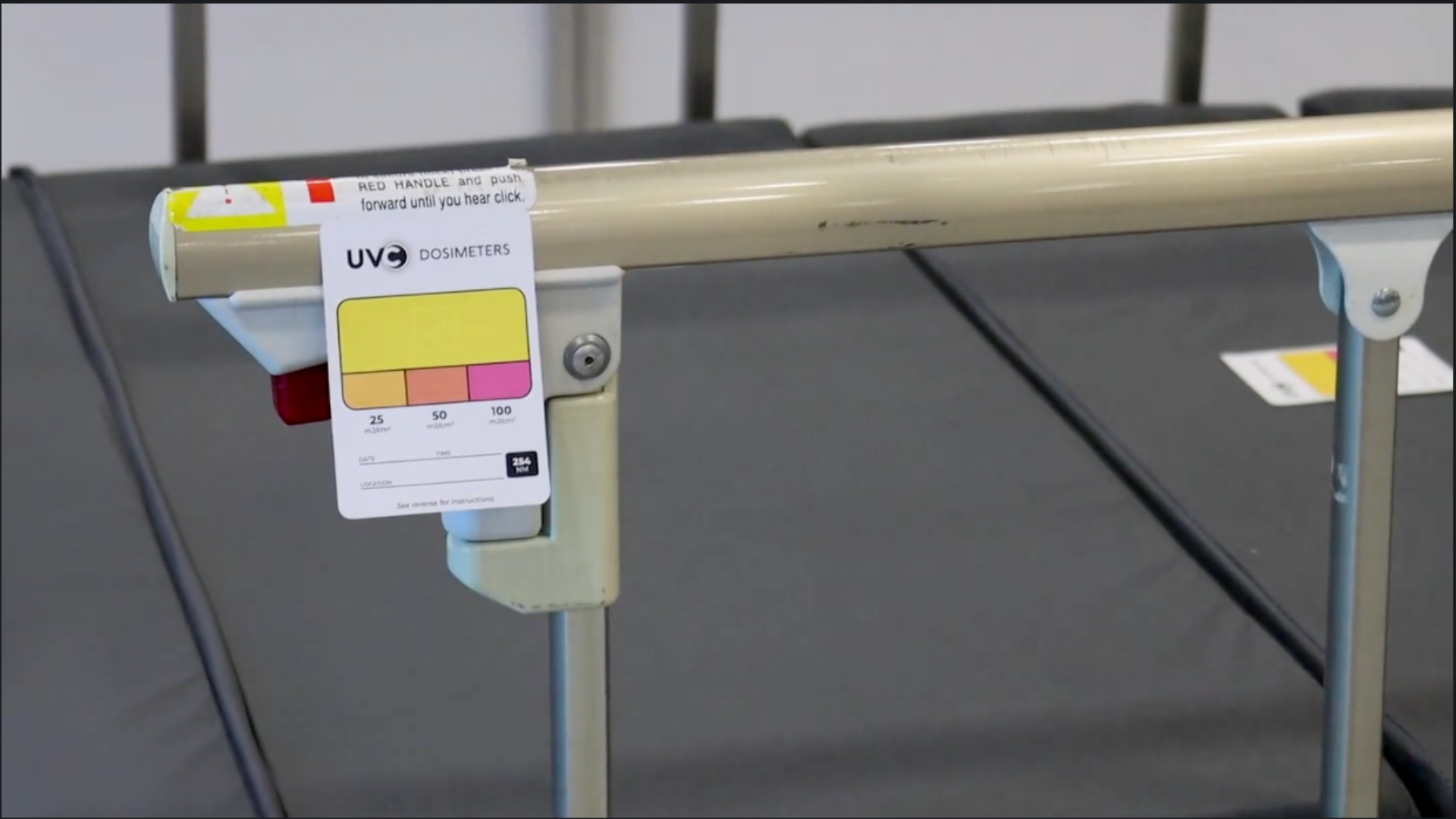

UV dosimeters operate on the principle of photochromic reaction. They contain materials that change color when exposed to UV light, with the degree of color change correlating to the amount of UV exposure. This process provides a visual indication of the UV dose received.

There are various types of colorimetric UV dosimeters available in the market. Choosing the right type of dosimeter depends on your specific application and requirements.

Intellego’s UV dosimeters are designed for different wavelengths, such as 222 nm, 254 nm, 395 nm, and so on, catering to various UV light sources, including LED and pulsed xenon.

Dosimeters also come in convenient forms like stickers or indicator cards, making them easy to use in different settings. Some are specifically tailored for LED UV light sources, while others are optimized for traditional UV lamps. Some are even made for the specific needs of the end user. What we’re trying to say is that there are a variety of dosimeters that do different things, and choosing the right one is vital.

Ensuring Accurate UV Dosimeter Readings

Accurate dosimeter readings are crucial for effective disinfection and curing. Here are key factors to consider:

STORAGE

Proper storage is essential for maintaining dosimeter accuracy:

- Keep dosimeters at room temperature

- Store in original packaging and close tightly

- Avoid exposure to direct sunlight or UV light sources

PLACEMENT

- Identify high-touch surfaces and critical areas in the room

- Place dosimeters on these surfaces, facing the UV light source

- Distribute dosimeters evenly throughout the space

- Include areas that might be shadowed or obstructed

- Position some dosimeters at different heights

For UV Curing:

- Position dosimeters on the same plane as the surface being cured

- Include areas that might receive less direct UV exposure

- Use multiple dosimeters for comprehensive coverage

LOGGING READINGS

Record your dosimeter reading immediately after the UV cycle has ended. This ensures the most accurate data, as waiting too long may result in further color changes.

INTERPRETING READINGS

Observe the new color of the photochromic area after UV exposure

- Match it to the reference color chart provided

- Note the corresponding numerical value

This process verifies whether your curing or disinfection process has achieved the required UV dose.

TRANSLATING DATA INTO PATTERNS

One of the key benefits of consistently using dosimeters is the ability to translate the collected data into actionable patterns. By analyzing the results over time, you can:

- Identify areas consistently receiving insufficient UV exposure

- Detect variations in UV intensity across different surfaces or equipment

- Recognize patterns related to equipment usage, such as frequency and duration of use or environmental factors

- Optimize placement of UV light sources for more uniform coverage

- Adjust exposure times or intensities to improve overall disinfection efficacy

REGULATORY CONSIDERATIONS

It’s important to note that while UV dosimeters are valuable tools, they are not currently recognized as medical devices by regulatory bodies like the FDA. However, they play a crucial role in validating UV disinfection processes, which is essential for maintaining safety standards in healthcare settings.

Conclusion

Proper use of Intellego’s UV dosimeters is crucial for ensuring the success of UV disinfection and curing processes. By understanding how these tools work, selecting the appropriate type, and following best practices for storage, placement, and interpretation, you can ensure a more accurate and reliable UV measurement.

Remember, each step in the process—from storage to placement, logging, and interpretation—plays a vital role in the overall effectiveness of your UV applications. By adhering to these guidelines, you can enhance your operations’ safety and quality while optimizing your UV systems’ performance.

Mastering UV dosimeters empowers you to maintain consistent, verifiable results in your UV applications, whether in healthcare settings for disinfection or manufacturing environments for curing. This knowledge allows you to confidently rely on your UV processes, knowing they are accurately monitored and validated.

Intellego Technologies is a research and development company, headquartered in Solna, Sweden. Founded in 2011, Intellego has grown to become the global leader in colorimetric indicators that are utilized worldwide to visually validate the dose of ultraviolet irradiation delivered to surfaces. Through its patented photochromic technology, Intellego manufactures standard and customized indicators that make the benefits of ultraviolet light visible and promotes the safe, effective and efficient use of UV applications. Intellego’s products support better outcomes with ultraviolet devices in healthcare, food and beverage manufacturing, environmental services, and more. For more information about Intellego, visit Intellego-Technologies.com. For more information on Intellego’s line of colorimetric indicators, visit UVCdosimeters.com.